Description

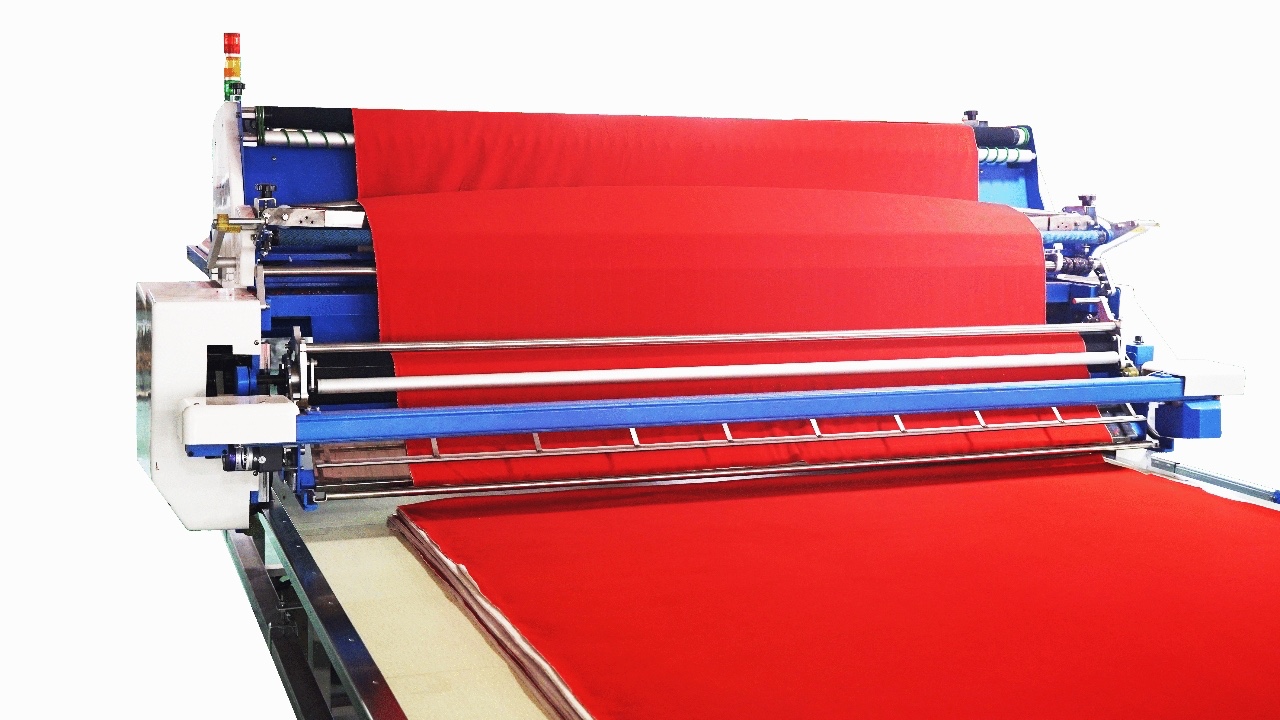

Machine Structure----positive side, machine use most of overseas brand electric parts to guarantee it work stably and lower failure rate, increase of service life furthest. Meanwhile, save fabric, save cost ,enhance fabric spreading precision, refuse much more waste.

Machine Structure----negative side, machine use aluminum material instead of heavy iron, make it more lighter, more stronger, not rust easily, not out of shape, running fast, save energy .

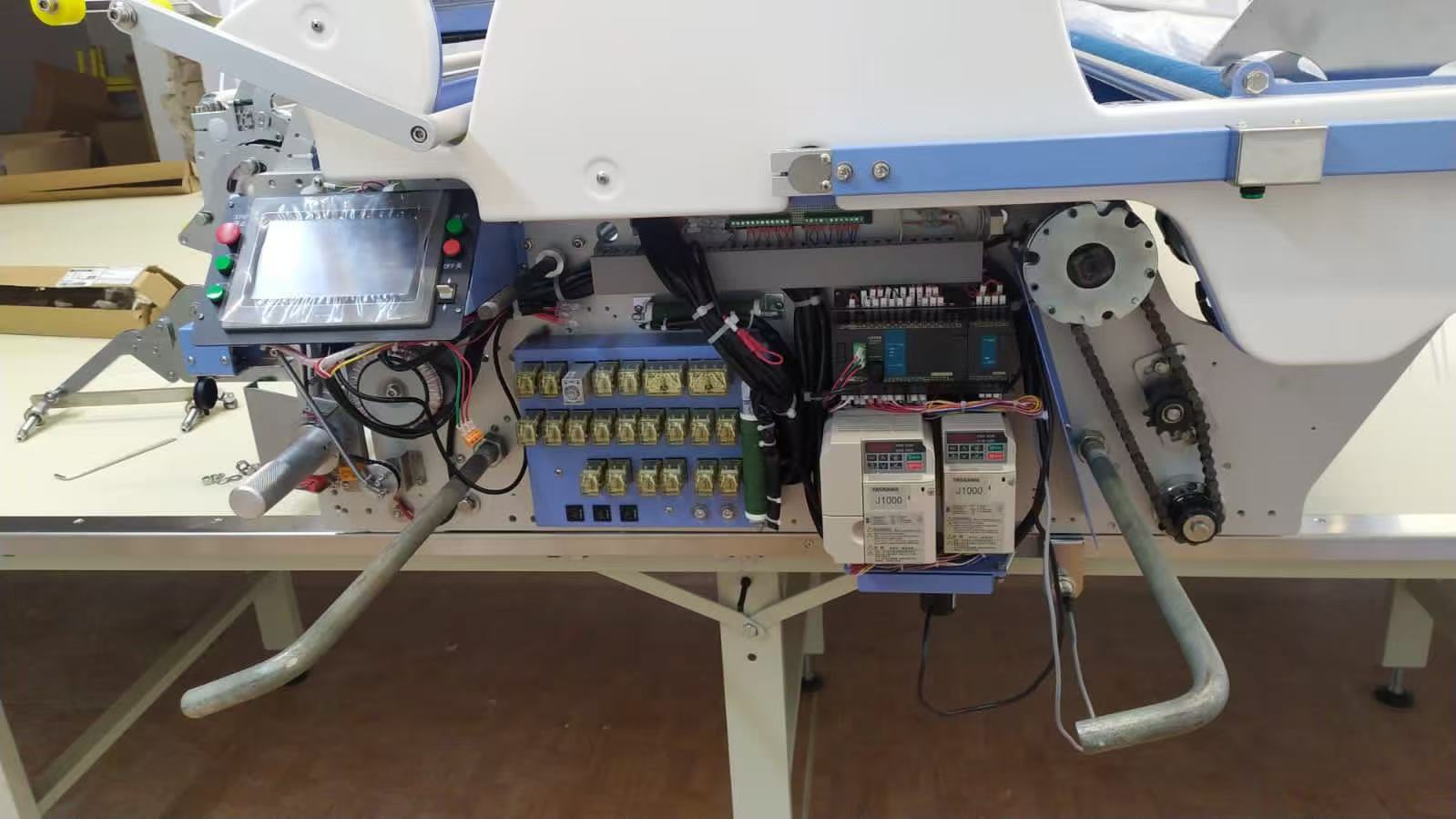

Why we machine operate steady and low failure rate ---------that is we are using domestic or international famous and expensive electronic parts.

You may need match automatic multilayer fabric cutting machine

You may need fabric spreading standard table(without blowing motor) or air blowing table(with motor)

You may need moving power rail

Customer factory demo machine presentation

We manufacturer

Package

1,KW-190 Spreading Machine L*W*H=2900*2280*1240mm,GW/NW:680/500KGS

2, 12 meter length Air Blowing Table L*W*H=2280*1270*1350mm,GW/NW:790/730KGS

3, 12 meter length Moving Power Rail L*W*H=3250*150*310mm,GW/NW:55/38KGS

The customer we received

The expo we attended

*One set fully automatic fabric spreading machine system must include Machine Head + Table +Power Rail( supply moving electric power for running the spreading machine ), besides then add optional parts according to customers fabric specification and needs.

*You should inform us basic fabric specification you may know such as :

A. Rolled Fabric Width Maximum

B. Rolled Fabric Weight Maximum

C. Rolled Fabric Diameter Maximum

D.The Longest Fabric Distance For Spreading.

E. Whether Need Zigzag Spreading(single and double).

*Or you can write our pre-sales questionnaire and send to us as below or download word:Pre-sales questionnaire

We Provide soft documents when shipping machine as blow:

*Machine Head + Spreading Table + Power rail ----Installation documents and video with English subtitles + spare parts price list+operation video+manual book , eliminate your worries .